Sulfatech

High-Performance Bioreactor for Anaerobe Applications

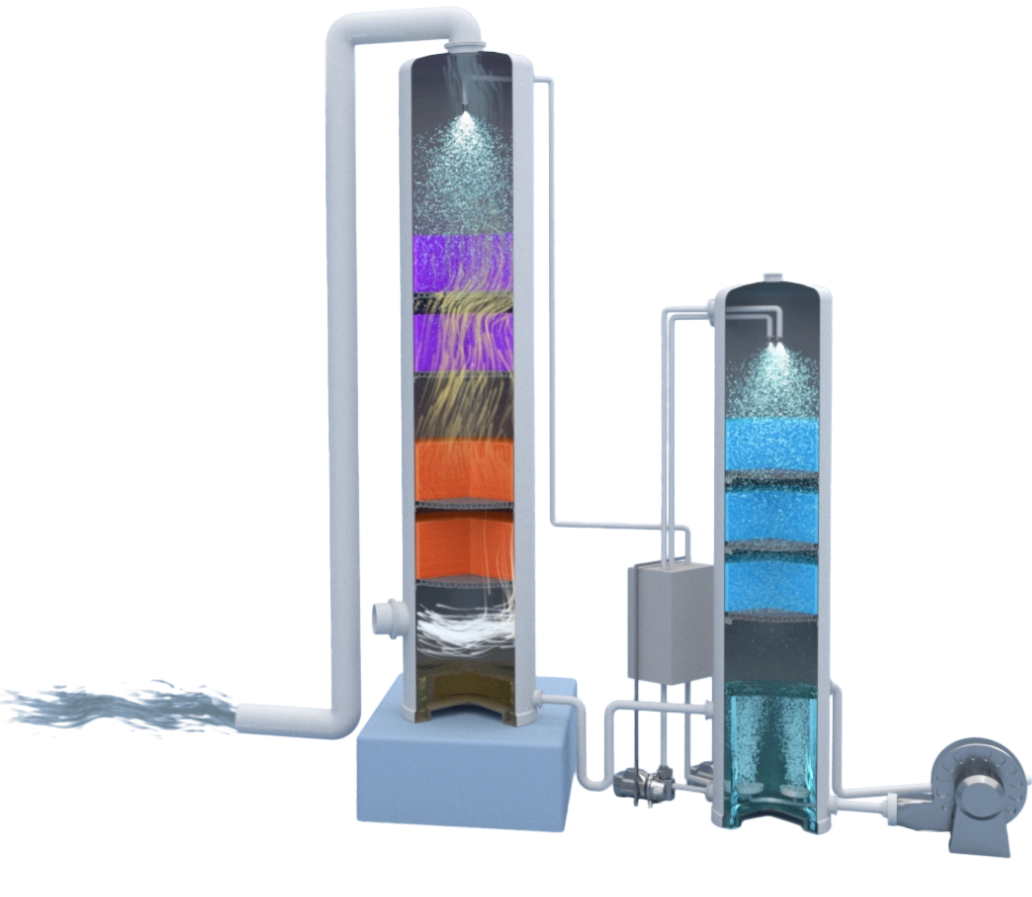

SULFATECH is an anaerobic gas scrubber used to sweeten sour gas in oil refineries and remove harmful sulfur emissions from gas in “waste to energy” projects fully biologically.

SULFATECH is an anaerobic gas scrubber used to sweeten sour gas in oil refineries and remove harmful sulfur emissions from gas in “waste to energy” projects fully biologically.

Our performance-proven SULFATECH System offers a highly efficient and cost-effective alternative to historical methods of reducing sulfur emissions, able to eliminate over 99.5% of H2S and SO2. In contrast to amine treatment, thermal oxidation, or caustic scrubbing, AZZURO’s technology provides expanded capabilities for treatment of H2S, SO2, COS, CS2 and mercaptans while offering higher reliability and reduced maintenance, all at significantly lower installed cost.

Aerobe bioreactor used to remove sulfur emissions

Removes over 99.5% H2S and other toxic sulfur compounds

Flow rates up to 20,000 cfm and H2S concentrations up to 20,000 ppm

An adaptive and self-regulating process that uses no chemicals and operates at ambient temperature and pressure

Consistent performance, few moving parts, extremely high reliability, and near zero maintenance

Modular design easily configurable for a wide range of applications

Simple installation, minimal disruptions to operations, and reduced steam consumption allow CAPEX to be recovered in as little as 24 months

The anaerobic system keeps all gas free of oxygen, which is always undesirable and an explosion risk

No chemicals or annual media change-outs reduces your carbon footprint and creates no waste by-products

Forward-thinking design meets increasingly stringent government regulations on sulfur emissions

Hydrocarbon recovery is best served with our bioreactor versus amine or caustic scrubbing—thanks to higher reliability, reduced maintenance and lower capital cost.

Learn More >

With microbiology at our core, we transform carefully cultivated bacteria into a giant ecosystem to treat polluted air and sour gas emissions.

Learn More >

Expanded capabilities for treatment of H2S, SO2, COS, CS2 and mercaptans now come at a lower cost with less maintenance.

Learn More >We are always looking to make new contacts and meet companies keen to find out more about our products and services. Whether you have a project you want our engineers to take a look at, require more information, or just want to say “Hi,” please reach out and a representative will get back to you shortly.

Get in touch