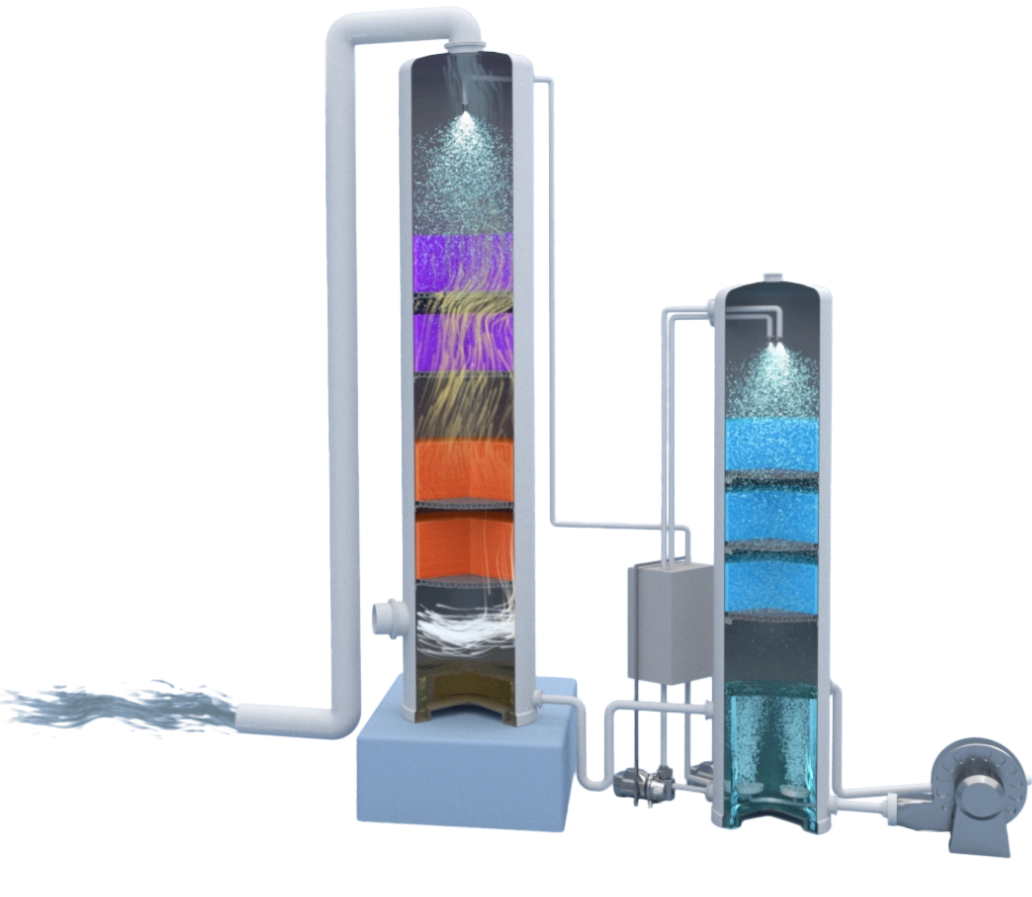

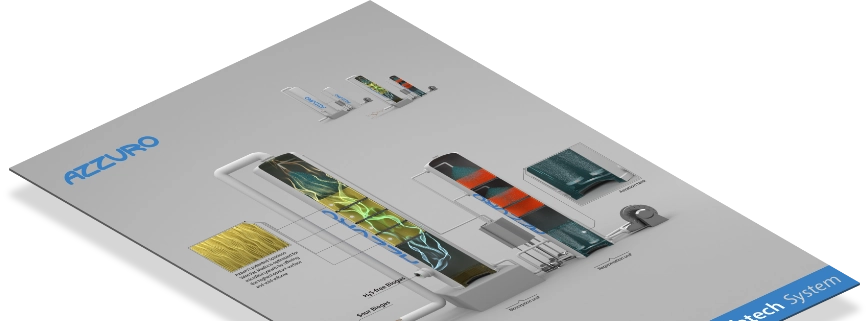

First, SULFATECH absorbs H2S from biogas or sour gas in an anaerobic chamber. Next, it pumps the gas into an aerobic biotrickling filter, where the H2S is oxidized into sulfuric acid (H2SO4).

The biogas flow stays in the anaerobic zone, where a “biological slurry” washes it, absorbing and dissolving the H2S. The aerobic biotrickling unit drains 3-5% sulfuric acid, which then returns to the biogas washing chamber. This chamber, still containing the biological slurry, is ready to scrub H2S from the methane (CH4) again.

To maintain the correct sulfuric acid concentration and salt level, a small percentage of the flow is refreshed with potable water.

Finally, clean gas exits the unit, and the process starts again. Because of the anaerobic and acidic environment, the biological reduction of methane is minimal.