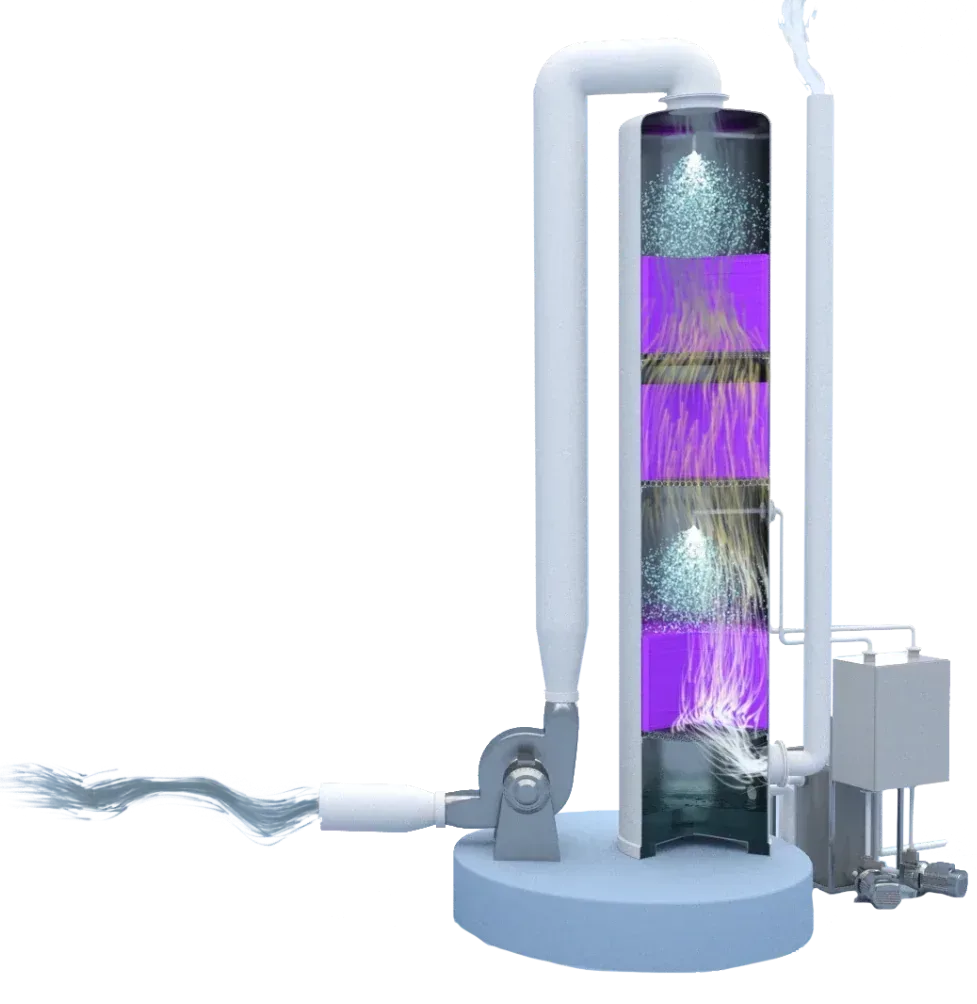

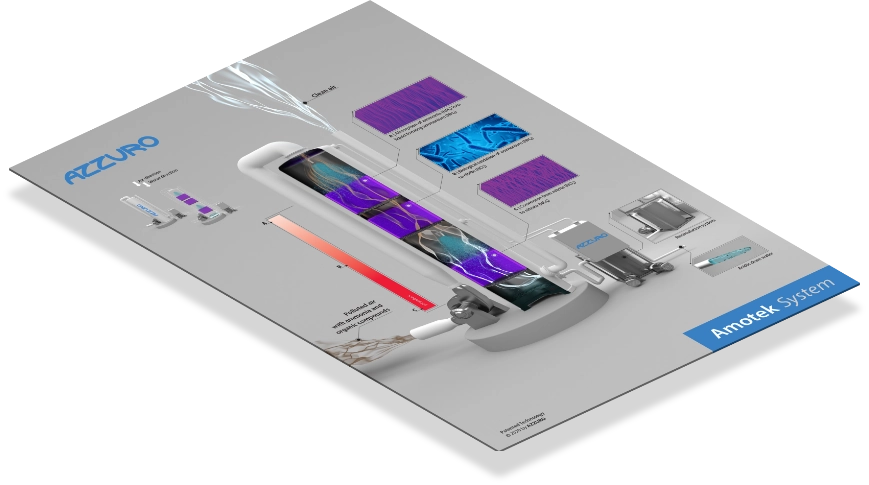

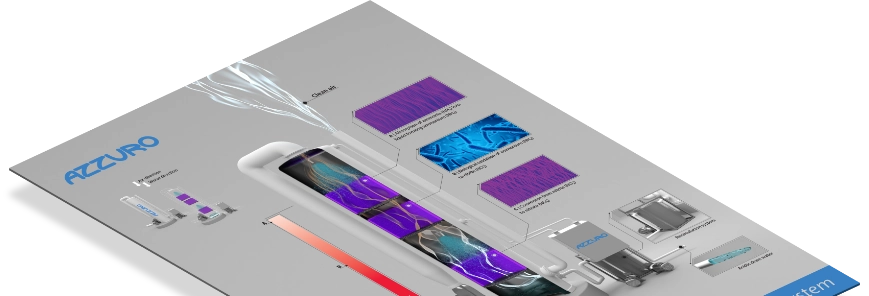

Amotek

Hybrid Bio-Chemical Reactor for Ammonia Removal

Specially designed for removing ammonia, AMOTEK is the world’s first hybrid bio-chemical reactor that doesn’t require chemical dosing – suitable for the agricultural sector as well as paper mills, composting facilities and other industries.